What Is a Strapping Machine and Why Does Your Business Need One?

What Is a Strapping Machine and Why Does Your Business Need One?

Blog Article

Exactly How a Strapping Maker Can Improve Your Storage Facility Efficiency

In today's busy warehousing setting, performance is crucial. Strapping Machine. You may locate that automating your strapping process can drastically improve operations. With the right maker, you can reduce labor prices and lessen plan damage throughout transportation. Not all strapping machines are produced equal. Recognizing what to seek and exactly how to integrate these makers into your existing workflow is important for optimizing their advantages. Allow's discover what makes a strapping machine an essential device for your stockroom

The Function of Strapping Machines in Modern Warehousing

In today's busy warehousing atmosphere, strapping equipments play a necessary function in improving performance and efficiency. You count on these machines to protect packages tightly, decreasing the risk of damages during transit. Instead of by hand covering and strapping items, you can use automated options that save time and lower labor costs.Strapping devices help simplify your process by quickening the packaging process. They guarantee uniformity in just how products are packed, allowing you to maintain high criteria in product packaging. You'll locate that using a strapping equipment reduces the demand for added products, consequently optimizing your supply chain.Moreover, these makers are versatile to different plan sizes and forms, making them functional devices in your storage facility. By incorporating strapping equipments into your procedures, you'll not just enhance efficiency however also produce a more reliable and well organized work setting, allowing your team to concentrate on core tasks.

Advantages of Automating the Strapping Refine

Automating the strapping process not only conserves time however additionally considerably boosts your stockroom's overall efficiency. By removing hands-on strapping, you lower labor costs and lessen the danger of human error. This indicates your team can focus on more important tasks, enhancing process efficiency.Additionally, automated strapping makers constantly apply the appropriate stress and safe packages extra accurately, making certain that your products are well-protected throughout transportation. You'll see less damaged items, which can lead to reduced returns and enhanced client satisfaction.Moreover, automating this procedure permits for faster throughput, indicating you can ship much more orders in less time. This agility can give you an one-upmanship in today's hectic market. Generally, buying automated strapping improves your procedures, enhances accuracy, and can ultimately lead to higher profitability for your stockroom. Accept this technology and view your performance rise.

Secret Functions to Try To Find in a Strapping Machine

Sorts Of Strapping Machines and Their Applications

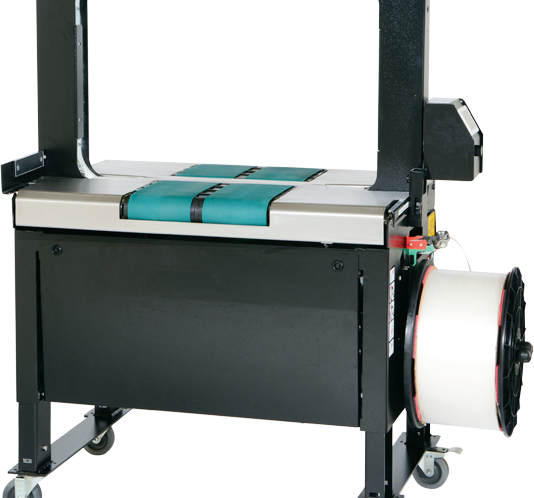

Strapping machines been available in various types, each made to fulfill details operational needs in a warehouse. Semi-automatic strapping makers allow you to manually feed the strap while the maker does the securing and reducing. This is optimal for lower quantity operations where versatility is vital. There are completely automatic machines, excellent for high-speed environments. They immediately feed, tension, and seal straps, enhancing performance markedly.Another option is handheld strapping devices, which use flexibility and simplicity for limited spaces or small work. Think about a durable strapping equipment made to handle larger products safely if you deal with heavy loads. Lastly, electrical strapping machines give constant tension for uniform outcomes, making them an excellent choice for high quality control. By recognizing the different types, you can choose the ideal strapping device that straightens with your warehouse's certain requirements, improving total productivity.

Integrating Strapping Equipments Into Existing Workflow

Integrating strapping machines into your existing workflow can significantly simplify procedures and boost productivity. Beginning by assessing your current packaging procedure to recognize traffic jams. Identify where strapping can add value, whether it's protecting boxes for delivery or bundling products for storage.Next, pick the ideal sort of strapping equipment that fits perfectly right into your configuration. See to it it's compatible with your packaging materials and can manage your volume needs. Training your staff is important; they need to comprehend just how to run the device effectively and safely.Consider positioning the strapping machine near packing terminals to minimize motion. This method, you'll lower time invested on product packaging jobs. Keep an eye on the assimilation process and gather comments from your team. Readjust as needed to optimize performance. By attentively including strapping equipments, you'll improve your process, minimize labor costs, and eventually enhance overall storage facility performance.

Case Researches: Success Stories From Storehouses

Effective warehouses typically share stories of how strapping equipments transformed their operations. A large circulation center faced hold-ups throughout peak periods due to hands-on strapping approaches. After introducing a fully automated strapping device, they saw a 30% boost in packaging speed. Orders that as soon as took hours to prepare were currently finished in mins, enabling faster delivery and improved customer satisfaction.Another warehouse satisfying ecommerce experienced frequent item damages throughout transportation. By implementing a strapping equipment, they safeguarded plans more properly, reducing damages prices by 40%. This not only conserved prices on replacements but also improved their track record for reliability.In both instances, the intro of strapping devices streamlined operations and raised performance. You can see exactly how these success stories illustrate the substantial benefits of upgrading your stockroom procedures. Embracing this innovation can be the trick to launching your storehouse's full potential.

Future Trends in Strapping Technology and Storage Facility Performance

As you look in advance, consider just how automation and robotics are reshaping strapping technology in storehouses. You're most likely to see a change towards lasting products and wise technology that enhances performance. Welcoming these trends can greatly enhance your functional productivity and environmental effect.

Automation and Robotics Integration

Lasting Strapping Materials

The promote higher efficiency in warehouses goes hand in hand with a growing concentrate on sustainability, especially when it concerns strapping products. You can enhance your procedures by picking green options like eco-friendly polyesters or recycled polypropylene - Strapping Machine. These materials not just decrease your ecological footprint yet likewise maintain toughness and integrity. By adopting sustainable strapping, you show your commitment to green methods, which can improve your brand photo and draw in eco mindful customers. Several distributors are currently offering innovative options that integrate toughness with sustainability, ensuring you don't give up performance. Changing to these materials can cause set you back financial savings also, provided their potential for lowering waste and improving recyclability in your supply chain

Smart Technology Advancements

With innovations in smart modern technology, strapping makers are ending up being extra reliable and straightforward than in the past. You'll find features like real-time surveillance and automated changes that assist simplify your procedures. These equipments can currently incorporate with storehouse management systems, permitting far better stock tracking and lower errors. Imagine having the ability to track each strap's stress and quality immediately, making certain peak efficiency without manual checks. Furthermore, anticipating analytics can anticipate upkeep needs, minimizing downtime. As you accept these innovations, you'll not only boost performance however additionally boost workplace security. Investing in smart strapping innovation is a smart option for future-proofing your storage facility and staying affordable in an ever-evolving market. Welcome the change, and see your effectiveness skyrocket!

Often Asked Concerns

What Is the Average Lifespan of a Strapping Maker?

The ordinary life expectancy of a strapping machine generally ranges from 5 to one decade, depending upon use and maintenance. Routine care can extend its life, guaranteeing you get one of the most value from your financial investment.

Just How Much Maintenance Do Strapping Makers Need?

Strapping machines need regular upkeep to guarantee peak performance. You need to check components frequently, tidy the maker, and replace worn parts as needed. Adhering to the manufacturer's guidelines will aid you minimize downtime and expand the equipment's life-span.

Can Strapping Machines Take Care Of Various Strap Sizes?

Yes, strapping equipments can manage different strap dimensions. You just need to readjust the setups or select a device developed for convenience. This adaptability assists you efficiently manage numerous product packaging demands in your procedures.

Are Strapping Machines Energy-Efficient?

Yes, strapping machines can be energy-efficient. They usually make use of much less power than hand-operated techniques, lowering total power intake. By choosing the appropriate version, you'll Continued save power and lower expenses while preserving performance in your procedures.

What Security Includes Should Strapping Machines Include?

When choosing a strapping machine, you should search for functions like emergency stop buttons, security guards, and automated tension changes. These improvements aid protect drivers and keep a secure workplace in your storage facility. You'll locate that using a strapping maker minimizes the requirement for extra products, consequently maximizing your supply chain.Moreover, these devices are versatile to numerous package sizes and forms, making them functional devices in your storehouse. When picking a strapping device, it's necessary to take right into account numerous crucial attributes that can substantially influence your storage facility operations. Semi-automatic strapping equipments permit you to by hand feed the strap while the equipment does the reducing and sealing. Training your personnel is my response essential; they need to understand just how to operate the maker successfully and safely.Consider putting the strapping maker close to packaging terminals to decrease motion. Successful warehouses frequently share tales of how strapping equipments transformed their operations.

Report this page